The Truth About Transit Tour will visit 19 cities across the United States from June into October. Participants will test drive Ford's all-new Transit van on a closed course specially designed to let them evaluate Transit's technology, handling and versatility.

5/31/14

The Truth About Transit Tour -The All-New Ford Transit Van

The Truth About Transit Tour will visit 19 cities across the United States from June into October. Participants will test drive Ford's all-new Transit van on a closed course specially designed to let them evaluate Transit's technology, handling and versatility.

5/30/14

How Ford Quietly Went About Early Testing of New F-150 Cargo Box with Real Customers in the Toughest Conditions

- Beginning in 2011, at job sites including a Nevada gold mine and a Pennsylvania dam, as well as in servicing power lines in Appalachia, six prototype F-150 pickups with high-strength, aluminum-alloy cargo boxes have been quietly tested in the hands of longtime Ford fleet customers

- Extreme real-world customer testing early on has helped prove durability of aluminum alloy and determine final cargo box design, ensuring the all-new Ford F-150 will be the toughest F-150 yet

- First time Ford has given customers advanced prototype vehicles so far ahead of production

Ford Motor Company went beyond its labs to test a key part of the all-new Ford F-150. The company embedded six prototype pickups – each with an experimental aluminum-alloy cargo box – at some of its fleet customer job sites then quietly went about evaluating the design and engineering of the next-generation pickup in the toughest conditions.

Three longstanding Ford fleet customers, unaware of Ford’s experiment, took delivery of prototype F-150s with current steel bodies and all-new, high-strength, aluminum-alloy cargo boxes in 2011. Three years later, these fleet customers and the Ford team who built the prototype trucks are convinced the new 2015 Ford F-150 will be the toughest truck the company has ever made.

“Our customers demand the highest levels of toughness and productivity – so we wanted to test the truck outside, in the harshest conditions and in the hands of real customers – with no limits,” said Larry Queener, program manager for the new F-150. “But we did not want these customers to know what was different. So, when we gave them the prototype vehicles, we told them to use the trucks like their other hard-working Ford trucks, and we would be back to follow their progress.”

Denis Kansier, F-150 prototype lead engineer, visited the customer sites every three months to check on the integrity of the vehicles and identify possible adjustments to the design of the new Ford F-150.

“This secret testing almost immediately yielded results and lessons we have rolled into the all-new F-150,” said Kansier. “For example, we made the cargo box floor thicker to improve strength, and we made modifications to the tailgate based on lessons we learned through customer usage.”

The six-vehicle fleet accumulated more than 350,000 miles in just more than two years.

Blind testing with customers

The job sites where the real-world testing was done were chosen for the tough nature of the work these fleet customers do there – from picking up and hauling heavy objects, like 40-pound pintle hitches used for heavy towing, to rolling over unforgiving off-road terrain. The customers were given two prototype vehicles each. The customers and the sites they worked on include:

- Barrick Gold Corporation, Elko, Nevada: The Barrick surveying team drove the vehicles through severe terrain at the company’s Bald Mountain and Cortez mines, including travel into mine pits before and after blasting. The prototype F-150 trucks are still being driven between 100 and 300 miles a day, and have accumulated more than 150,000 miles between them

- Walsh Construction, Holtwood, Pennsylvania and Birmingham, Alabama: Walsh Construction was selected for the severity of use at two of its work sites – first, a hydroelectric dam in Lancaster, Pennsylvania, then a highway interchange construction site in Birmingham, Alabama

- Regional utility company in North Carolina: One F-150 prototype was assigned to a meter reading crew that drives up steep mountain roads; the second truck was assigned to line crews that drive up overgrown paths to replace old poles and electrical lines. The meter readers removed the truck’s tailgate to improve visibility – an alteration Ford engineers responded to by incorporating height modifications into the final F-150 design. The trucks at these sites are still being driven an average of 200 miles a day

As the testing of these six F-150 prototypes ensued, drivers began to notice differences compared to typical steel truck beds. One of the differences they noticed was a lack of rust.

“They told us they noticed the boxes did not produce red surface rust when heavy use scratched through the paint,” said Kansier.

The fleet customers were informed of the modified, high-strength aluminum-alloy cargo box at the reveal of the all-new F-150 at the North American International Auto Show in January. The prototype trucks are still in use at these three companies.

Tough testing strategy

Ford’s extensive testing strategy for the new F-150 includes three phases that will allow engineers to understand how each truck stands up under an array of harsh conditions: “We Test,” which takes place in Ford labs, “They Test,” at fleet customer sites and “You Test,” in which consumers will have an opportunity to put the new truck through its paces.

In addition to testing by the three fleet customers, prototype F-150s have been tested in a number of real-world environments. Among them is Davis Dam – a durability route in a remote corner of northeast Arizona – where the F-150 climbed 13 miles pulling a maximum trailer load in 120 degree heat. In California’s Anza-Borrego State Park, an hour east of San Diego, the truck ascended a mountain of sand and rock with a 30-degree grade, sometimes reaching an altitude of 6,000 feet, 250 times over five days – all without fail.

5/29/14

Ford to Launch Advanced Steering Technology to Help Make Vehicles Easier to Maneuver, More Fun to Drive

- Ford’s Adaptive Steering – a new generation of steering technology – will be available within 12 months

- New technology improves steering feel at all speeds, making any vehicle easier to maneuver and more enjoyable to drive

- Housed entirely within the steering wheel, Ford’s newest steering technology is a smart solution that will benefit drivers in all driving conditions

Ford Motor Company is bringing to market a new generation of steering technology that will help make vehicles easier to maneuver at low speeds and in tight spaces. At higher speeds, the new technology will help make the vehicle more agile and fun to drive.

“First and foremost, all Ford Motor Company products have to offer a great driving experience,” said Raj Nair, Ford group vice president, Global Product Development. “This new steering technology can make any vehicle easier to maneuver and more fun to drive.”

Adaptive Steering changes

the ratio between the driver’s actions at the steering wheel – the

number of turns – and how much the front wheels turn. In traditional

vehicles, this is a fixed steering ratio. With Ford’s new Adaptive

Steering, the steering ratio continually changes with vehicle speed,

optimizing the steering response in all conditions.

At lower speeds, such as when pulling into a parking space or maneuvering in tight quarters, the new system makes the vehicle more agile and easier to turn, as it dials more steering into the road wheel. Each low-speed maneuver requires less turning of the steering wheel.

At highway speeds, the system further optimizes steering response, enabling the vehicle to react more smoothly and precisely to driver input. Adaptive steering can help the driver feel more comfortable and can make any drive more enjoyable.

At lower speeds, such as when pulling into a parking space or maneuvering in tight quarters, the new system makes the vehicle more agile and easier to turn, as it dials more steering into the road wheel. Each low-speed maneuver requires less turning of the steering wheel.

At highway speeds, the system further optimizes steering response, enabling the vehicle to react more smoothly and precisely to driver input. Adaptive steering can help the driver feel more comfortable and can make any drive more enjoyable.

Ford’s system uses a precision-controlled actuator placed inside the steering wheel, and requires no change to a vehicle’s traditional steering system. The actuator – an electric motor and gearing system – can essentially add to or subtract from a driver’s steering inputs. The result is a better driving experience at all speeds, regardless of vehicle size or class.

Adaptive Steering will be available on select vehicles beginning next year. The system was developed for production by Ford in collaboration with Takata, a leading supplier of automotive steering and safety systems and a Ford Aligned Business Framework partner.

5/28/14

New Ford Transit Debuts with Industry-First Ford Paint Technology that Improves Durability and Sustainability

- All-new Ford Transit uses industry-first paint technology that is more durable than other commercial van exterior coatings

- Paint applied through the new process will retain 90 percent of its gloss at four years in service*

- New two-wet monocoat paint technology significantly reduces energy and water use, and lowers carbon dioxide and other emissions at Kansas City Assembly Plant

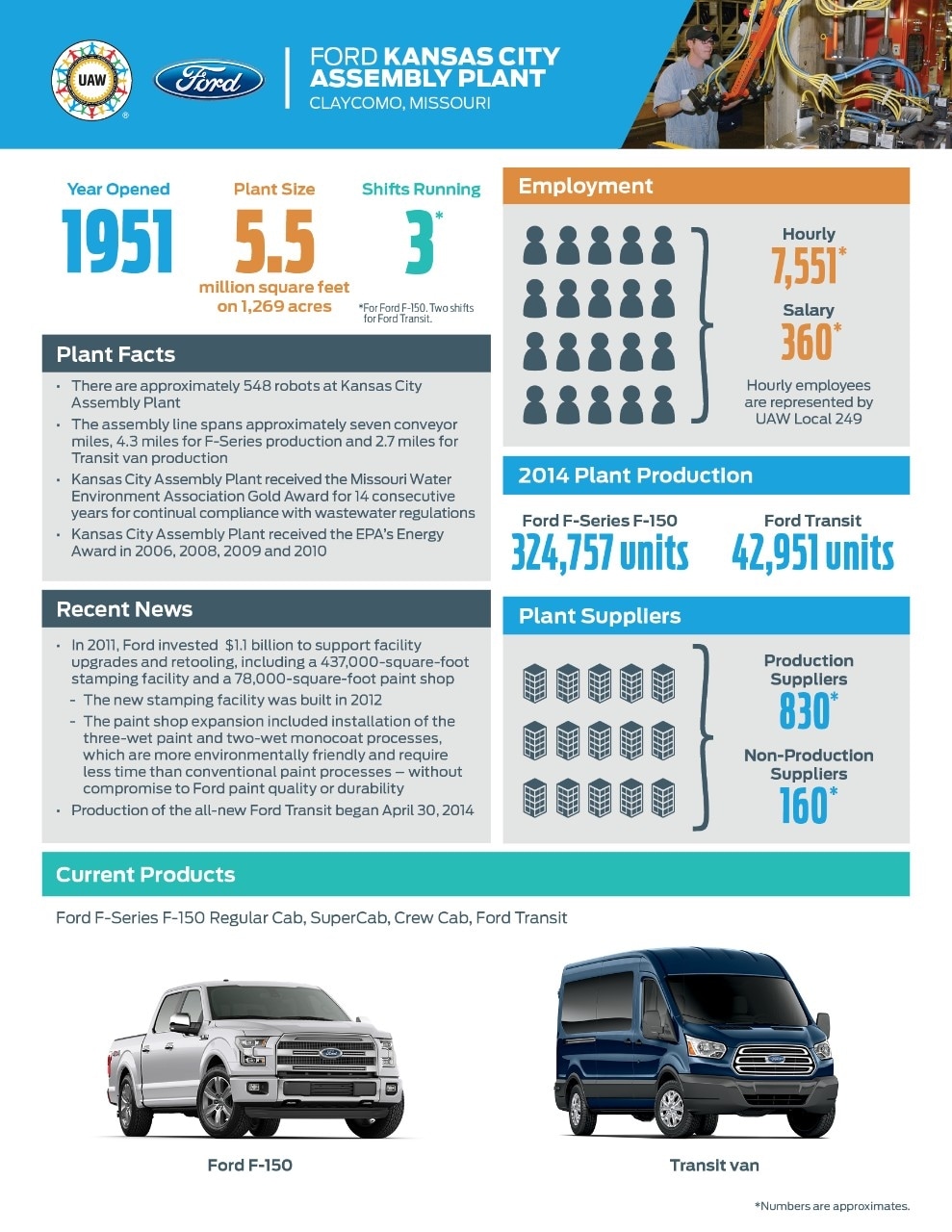

The all-new Ford Transit makes its North American debut with more durable paint, thanks to an industry-first paint technology now in use at Kansas City Assembly Plant.

Ford celebrated the start of North American Transit production at Kansas City Assembly Plant on April 30, and vans will be available on U.S. and Canadian dealer lots this summer.

The Transit vehicles built in Kansas City are the first to use the new two-wet monocoat paint process developed by Ford and its paint suppliers. The technology results in more durable paint, uses less energy and water, and reduces carbon dioxide and particulate emissions compared with conventional paint processes

The new paint had to meet

or exceed “Built Ford Tough” standards, and was subjected to a battery

of tests that simulates typical conditions the vehicle will see during

10 years. The paint was tested for its resistance to chipping and

scratching, pollutants and sun exposure. Advanced weathering testing

indicates that paint applied with the new two-wet technology will retain

90 percent of its gloss at four years in service compared to 1 percent

gloss retention for paint applied using a conventional monocoat

process.*

“Durability was a critical consideration when we initiated this project,” said Dennis Havlin, Ford global paint engineering development and launch supervisor. “The advancements in paint chemistry enable us to deliver the appearance, performance and durability our customers demand.”

In addition to making paint tougher, the process reduces painting time and energy use by cutting the number of paint applications from three to two and the number of drying procedures from two to one.

It is another example of the innovative technologies Ford is implementing to support its global manufacturing strategies with regard to carbon dioxide emissions and water use. Ford plans call for a 30 percent reduction in carbon dioxide emissions per vehicle produced from 2010 to 2025, and a 30 percent reduction in water use per vehicle produced from 2009 to 2015.

The new paint process uses less energy and water, and reduces carbon dioxide and particulate emissions compared with conventional paint processes. The reduction in paint and energy consumed is expected to result in 9,500 tons fewer carbon dioxide emissions and a 35-ton savings in particulate emissions on an annual basis.* An innovative dry scrubber system will help save more than 10.5 million gallons of water.* Overall, the system should save 48,000 megawatt hours of electrical power,* enough electricity to power 3,400 homes.

The two-wet monocoat process uses a primer coat that requires only a few minutes of open-air drying time before the color coat is applied. The color coat is formulated with the same appearance and protection properties of the clear coat, which eliminates the need for a separate clear coat. The painted body is fully cured in an enamel oven after the color coat is applied. The total process removes one paint application step and one oven drying step when compared to conventional paint processes.

“Durability was a critical consideration when we initiated this project,” said Dennis Havlin, Ford global paint engineering development and launch supervisor. “The advancements in paint chemistry enable us to deliver the appearance, performance and durability our customers demand.”

In addition to making paint tougher, the process reduces painting time and energy use by cutting the number of paint applications from three to two and the number of drying procedures from two to one.

It is another example of the innovative technologies Ford is implementing to support its global manufacturing strategies with regard to carbon dioxide emissions and water use. Ford plans call for a 30 percent reduction in carbon dioxide emissions per vehicle produced from 2010 to 2025, and a 30 percent reduction in water use per vehicle produced from 2009 to 2015.

The new paint process uses less energy and water, and reduces carbon dioxide and particulate emissions compared with conventional paint processes. The reduction in paint and energy consumed is expected to result in 9,500 tons fewer carbon dioxide emissions and a 35-ton savings in particulate emissions on an annual basis.* An innovative dry scrubber system will help save more than 10.5 million gallons of water.* Overall, the system should save 48,000 megawatt hours of electrical power,* enough electricity to power 3,400 homes.

The two-wet monocoat process uses a primer coat that requires only a few minutes of open-air drying time before the color coat is applied. The color coat is formulated with the same appearance and protection properties of the clear coat, which eliminates the need for a separate clear coat. The painted body is fully cured in an enamel oven after the color coat is applied. The total process removes one paint application step and one oven drying step when compared to conventional paint processes.

The new paint procedure is being used for white-colored vehicles, which account for 80 percent of Ford Transit production at Kansas City Assembly Plant. As each color must be developed uniquely for the two-wet monocoat process, other colors will be considered based on demand. A conventional three-wet process – primer, base coat, clear coat – remains in use for metallic-colored vehicles.

Gaining production efficiencies

The two-wet monocoat system helps increase production efficiency. The more streamlined process takes the vehicle body through an electrostatically bonded corrosion-resistance (E-coat) bath. The Transit body remains on a carrier that is lowered into the E-coat by four pendulums, rather than being manually removed from the carrier and attached to chains to be taken down, only to have to repeat the same steps before moving on to the paint booth.

The pendulums take the vehicle body into and out of the bath at steep angles, reducing the length of the bath by as much as 320 feet. Transit’s paint operation requires less space than that used in production of the smaller Ford Fiesta.

“The two-wet monocoat process allows us to design a system considerably smaller than a conventional paint shop, especially with regard to a vehicle of this size and complexity,” said Havlin. “Because painting time is cut down, the technology enables greater productivity using less equipment.”

Environmental savings

A conventional paint process uses water filtration – known as a wet scrubber system – to remove the overspray from the air in the paint booth that produces sludge. The new dry scrubber system pumps the air through a filter containing limestone that can be recycled. The dry scrubber system alone reduces energy use and carbon dioxide emissions by 44 percent, cuts particulate emissions by 99 percent and uses 75 percent less water annually.*

* Data based on preliminary testing.

5/26/14

Memorial Day Why We Remember

To Those Who Serve, Thank You

5/25/14

Sounds of Assembly: Electronic Music Inspired by the Ford Focus

Electronic musicians Ataxia and Secrets tour Ford's Michigan Assembly Plant, utilizing sounds samples from Focus's assembly to create new tracks for Detroit's Movement festival.

5/24/14

All-New 2015 F-150 Most Patented Truck in Ford History – New Innovations Bolster Next-Generation Light-Duty Pickup

- 2015 Ford F-150 has more new Ford technology patents and/or patent applications than any truck in Ford history, offering customers innovative technologies throughout – everything from the tailgate to the front end

- All-new F-150 boasts more than 100 new Ford patents and/or patent applications, making this vehicle a benchmark for new technologies in Ford’s storied history of truck leadership

- A Ford-developed heat treatment method for aluminum alloy nearly doubles the strength of the material, helping achieve better dent and ding resistance while reducing weight

From its tailgate step to the LED spotlights found on the side mirrors, the next-generation 2015 Ford F-150’s new features and technologies make it the most patented truck in company history.

“The all-new F-150 is loaded with innovation,” said Alana Strager, Ford program analyst charged with tracking new innovations for the 2015 truck. “Ford engineers filed more than 100 new patents for technologies on this truck as they have worked to redefine the light-duty pickup for the next generation.”

Patents and patent applications abound for state-of-the-art technologies covering new features and breakthroughs that will benefit customers of the all-new 2015 F-150. The scope of these innovations includes every part of the truck – body, exterior, interior, chassis, design, electrical and engine – as well as its manufacturing processes.

Patenting a smarter truck

Examples of Ford’s state-of-the-art technologies on the new 2015 F-150 include segment-exclusive LED spotlights found on the side mirrors, innovative remote tailgate release and smart trailer tow features that make towing easier.

- Innovative LED side-mirror spotlights allow customers to

illuminate the side of the vehicle for tasks from setting up a campsite

to changing a tire

- Remote tailgate release automatically lowers the tailgate with the push of a button on the key fob – a first for a pickup truck

- Ford’s pioneering tailgate step has been completely reengineered

so it fully integrates into the tailgate, making it virtually invisible

when not in use. The tailgate drops down into position in one easy

motion. The grab handle is now housed inside the tailgate, which keeps

the inner surface of the tailgate uniformly flat

- BoxLink™ cargo management system includes lockable,

die-cast aluminum tie-down cleats, and provides a unique interface to

the box for improved flexibility and organization, as well as additional

locations for tie-downs. Available segment-first cargo ramps can be

stowed on the sides of the pickup box via the BoxLink system and mounted

quickly on the tailgate to enable easy loading of ATVs, motorcycles or

mowers

Other smart features never offered before on a Ford pickup include 360-degree camera view, integrated loading ramps stowed in the pickup bed, 400-watt power outlets inside the cab and LED headlights.

Patenting toughness

Mounted on an exceptionally strong and well-proven high-strength steel frame, the all-new Ford F-150 incorporates the latest high-strength, military-grade, aluminum alloys to form the body and cargo box.

The aluminum is heat-treated using a proprietary method developed by Ford engineers that nearly doubles the strength of the metal. Ford is first in the auto industry to use this methodology.

Additionally, Ford engineers have filed patent applications for spot welding methods, adhesives and hydroforming this first-of-its-kind truck.

“Ford is teaching the world how to build a next-generation truck, and the more than 100 patents filed by the F-150 team for technologies on the 2015 truck further proves these Ford engineers and designers lead the automotive industry in innovation,” said Strager.

5/23/14

Ford Dearborn Truck Plant Celebrates 10 Years of Sustainable Manufacturing; Prepares to Build All-New 2015 Ford F-150

- Along with Dearborn Truck Plant marking 10 years of sustainable manufacturing and 2.6 million units of Ford F-150 production, Ford Rouge factory tour celebrates its 10th year; a complete tour renovation starts this summer

- Dearborn Truck Plant upholds Ford’s blueprint for sustainability through its living roof and recycling programs; the facility has recycled more than 20 million pounds of cardboard, paper, plastic and wood since its opening

- Dearborn Truck Plant will begin building the all-new 2015 Ford F-150 in late 2014

Ford Motor Company is celebrating the 10-year anniversary of its groundbreaking Dearborn Truck Plant. As the centerpiece of Ford Rouge Center, Dearborn Truck Plant was conceived as Ford’s vision of sustainable manufacturing and has served as flagship for the company’s next generation of lean and flexible plants.

Dearborn Truck Plant has produced more than 2.6 million F-150 trucks since it opened in May 2004. Once home to the iconic Ford Mustang, the plant now has more than 3,600 employees on a three-crew operating pattern producing 1,200 F-150 trucks daily. Later this year, production of the all-new 2015 Ford F-150 gets under way at Dearborn Truck Plant.

F-150 is part of the Ford F-Series lineup, America’s best-selling truck for 37 consecutive years and America’s best-selling vehicle for 32 years.

“Dearborn Truck Plant has

set world-class standards for efficiency and environmentally friendly

manufacturing processes,” said Bruce Hettle, vice president, Ford North

America manufacturing.

“There is no better way to celebrate 10 years of top-notch manufacturing than gearing up to build the all-new F-150. The hardworking men and women of Dearborn Truck are excited to bring this Built Ford Tough truck to our customers.”

The plant is capable of building up to nine models on three vehicle platforms. It has close to 350 robots between its body and paint shops and final assembly area. This summer, the body shop will undergo a complete renovation in preparation to build the all-new F-150.

Living roof and sustainability efforts

Once noted as the world’s largest living roof by Guinness World Records®, and now the largest in North America, Dearborn Truck Plant’s roof has flourished as an environmental touchstone since its installation in 2004. At 10.4 acres, the living roof sustains a diverse ecosystem, removes carbon dioxide from the atmosphere and reduces energy use. It is part of an innovative storm water management system that reduces runoff and costs two-thirds less than a conventional water treatment process.

The facility maximizes the use of natural light and ventilation to reduce the financial and environmental costs of heating, cooling and powering the plant. The paint shop uses water-based primer and base coat systems that minimize volatile emissions while also maintaining paint quality.

Efforts are made to use as much recyclable packaging as possible to reduce the volume of waste. A total waste management system incorporating transportation, disposal, recycling, reclamation and reuse of plant waste is in operation at Dearborn Truck Plant. To date, the facility has recycled more than 20 million pounds of cardboard, paper, plastic and wood.

Ford Rouge factory tour

More than 1 million visitors from all over the world have taken the Ford Rouge factory tour, including racing legend Sir Jackie Stewart, U.S. Senate Majority Leader Harry Reid, former U.S. Secretary of Transportation Ray LaHood, former Speaker of the U.S. House of Representatives Dennis Hastert and former President of Mexico Vicente Fox.

A self-guided, six-part experience, the tour is designed to educate visitors on the history of Ford Rouge Center and provide a 360-degree look at how vehicles are made. Visitors are afforded the opportunity to view the final assembly process of Ford F-150 from an elevated walkway.

This summer, the tour program undergoes a renovation, which will include new films, exhibits and hands-on experiences tied to the launch of the all-new F-150.

“The Rouge factory tour is a true gem, in that it showcases the history and the legacy of Henry Ford’s industrial vision, while highlighting the innovation taking place at Ford today,” said Cynthia Jones, general manager, Ford Rouge factory tour. “As we evolve the tour, we plan to create something memorable that people young and old can enjoy for years to come.”

The tour has been recognized as one of 10 great places that inspire innovation by USA Today. It is ranked No. 4 on Time magazine’s “Detroit: 10 Things to Do” list.

2015 Ford F-150

Along with Kansas City Assembly Plant in Claycomo, Mo., Dearborn Truck Plant will be the production site of the all-new Ford F-150, which sets the standard for the future of trucks. The use of advanced materials – including more high-strength steel than ever in the frame and high-strength, military-grade, aluminum alloy throughout the vehicle body – improves durability while saving up to 700 pounds, giving customers greater towing, payload and fuel efficiency performance.

“There is no better way to celebrate 10 years of top-notch manufacturing than gearing up to build the all-new F-150. The hardworking men and women of Dearborn Truck are excited to bring this Built Ford Tough truck to our customers.”

The plant is capable of building up to nine models on three vehicle platforms. It has close to 350 robots between its body and paint shops and final assembly area. This summer, the body shop will undergo a complete renovation in preparation to build the all-new F-150.

Living roof and sustainability efforts

Once noted as the world’s largest living roof by Guinness World Records®, and now the largest in North America, Dearborn Truck Plant’s roof has flourished as an environmental touchstone since its installation in 2004. At 10.4 acres, the living roof sustains a diverse ecosystem, removes carbon dioxide from the atmosphere and reduces energy use. It is part of an innovative storm water management system that reduces runoff and costs two-thirds less than a conventional water treatment process.

The facility maximizes the use of natural light and ventilation to reduce the financial and environmental costs of heating, cooling and powering the plant. The paint shop uses water-based primer and base coat systems that minimize volatile emissions while also maintaining paint quality.

Efforts are made to use as much recyclable packaging as possible to reduce the volume of waste. A total waste management system incorporating transportation, disposal, recycling, reclamation and reuse of plant waste is in operation at Dearborn Truck Plant. To date, the facility has recycled more than 20 million pounds of cardboard, paper, plastic and wood.

Ford Rouge factory tour

More than 1 million visitors from all over the world have taken the Ford Rouge factory tour, including racing legend Sir Jackie Stewart, U.S. Senate Majority Leader Harry Reid, former U.S. Secretary of Transportation Ray LaHood, former Speaker of the U.S. House of Representatives Dennis Hastert and former President of Mexico Vicente Fox.

A self-guided, six-part experience, the tour is designed to educate visitors on the history of Ford Rouge Center and provide a 360-degree look at how vehicles are made. Visitors are afforded the opportunity to view the final assembly process of Ford F-150 from an elevated walkway.

This summer, the tour program undergoes a renovation, which will include new films, exhibits and hands-on experiences tied to the launch of the all-new F-150.

“The Rouge factory tour is a true gem, in that it showcases the history and the legacy of Henry Ford’s industrial vision, while highlighting the innovation taking place at Ford today,” said Cynthia Jones, general manager, Ford Rouge factory tour. “As we evolve the tour, we plan to create something memorable that people young and old can enjoy for years to come.”

The tour has been recognized as one of 10 great places that inspire innovation by USA Today. It is ranked No. 4 on Time magazine’s “Detroit: 10 Things to Do” list.

2015 Ford F-150

Along with Kansas City Assembly Plant in Claycomo, Mo., Dearborn Truck Plant will be the production site of the all-new Ford F-150, which sets the standard for the future of trucks. The use of advanced materials – including more high-strength steel than ever in the frame and high-strength, military-grade, aluminum alloy throughout the vehicle body – improves durability while saving up to 700 pounds, giving customers greater towing, payload and fuel efficiency performance.

When it arrives in showrooms later this year, the all-new F-150 will have undergone more than 10 million miles of torture testing to ensure it meets or exceeds Built Ford Tough standards.

In addition to an all-new 2.7-liter EcoBoost® engine offering, the 2015 F-150 features a complete lineup of powertrains to let customers tailor the toughest, smartest, most capable pickup truck ever to their needs. The 3.5-liter EcoBoost engine returns, an all-new normally aspirated 3.5-liter V6 debuts and there is an improved 5.0-liter V8.

5/22/14

All-New Ford F-650/F-750 Diesel Will Provide Best-in-Class Standard Horsepower and Torque

- 2016 Ford F-650/F-750 to offer three diesel power ratings, including best-in-class standard horsepower and torque

- Customers can pick the diesel engine power rating that best suits their needs, with no vocational restrictions

- Ford 6.7-liter Power Stroke® V8 turbo diesel engine is paired with commercial-grade six-speed Ford TorqShift® HD automatic transmission optimized for medium-duty vocations

Ford, America’s truck leader, announces the all-new F-650/F-750 medium-duty truck lineup with 6.7-liter Power Stroke® V8 turbo diesel will feature three engine power ratings, including best-in-class standard diesel horsepower and torque, and no vocational limits on top ratings.

The three diesel power levels available for the 2016 Ford F-650/F-750 are:

- 270 horsepower/675 lb.-ft. torque (best-in-class standard)

- 300 horsepower /700 lb.-ft. torque

- 330 horsepower/725 lb.-ft. torque

Multiple ratings provide customers with the flexibility to scale engine power to work applications and operations.

“While other medium-duty truck manufacturers restrict top horsepower and torque ratings to certain applications, such as emergency services, the all-new F-650/F-750 will arrive with no vocational restrictions,” said John Ruppert, general manager Ford Commercial Vehicle Sales and Marketing. “We’re giving our customers the power of choice to determine what’s best for their business.”

The second generation 6.7-liter Power Stroke V8 turbo diesel builds upon the success of the diesel engine found in the F-Series Super Duty lineup. The F-650/F-750 6.7-liter Power Stroke and commercial-grade six-speed TorqShift® HD automatic transmission have been developed and tested for medium-duty applications. The powertrain offers an unsurpassed five-year/250,000-mile limited warranty.

Ford is the only medium-duty truck manufacturer that designs and builds its own diesel engine and transmission combination – ensuring the powertrain will work seamlessly with all chassis components and vehicle calibrations. This approach enables Ford engineers to optimize vehicle performance across the entire lineup and further refine the powertrain to the specific needs of the customer.

“Engineering the truck and powertrain together is the best way to deliver a great product for the customer,” said John Davis, Ford commercial vehicle chief nameplate engineer.

Key innovations on the 6.7-liter Power Stroke V8 turbo diesel are its compacted graphite iron engine block that enhances durability and helps reduce noise, vibration and harshness. The reverse-flow layout places the exhaust inside the engine’s V-shape, while the air intake is positioned on the outside of the V. This segment-exclusive design naturally improves a variety of attributes.

Shorter airflow from the exhaust system to the turbocharger sitting between the engine’s cylinder banks improves turbo responsiveness – key to providing torque quickly to truck customers when they need it most. Positioning the turbo inside the engine’s valley helps isolate the engine’s hottest temperatures, aiding performance and efficiency while also reducing noise, vibration and harshness for improved driver comfort.

During testing, the 6.7-liter Power Stroke V8 turbo diesel endured the equivalent of 500,000-plus miles on an engine dynamometer, replicating the duty cycle of the harshest-use customer.

In addition to its Power Stroke diesel, Ford remains the segment-exclusive automaker to offer a gasoline-powered engine for a medium duty truck. The 330 horsepower, 440 pounds-feet of torque 6.8-liter V10 is now available for both F-650 and F-750 models with the TorqShift® HD six-speed automatic transmission. The 6.8-liter V10 can be factory-prepped for converting to compressed natural gas or liquid propane gas as cost-effective alternatives to gasoline.

The Ford F-650/F-750 anchors Ford’s Commercial Truck lineup – America’s best-selling line of commercial trucks for 29 years – giving vocational customers an unmatched one-stop shop to meet their needs, from a Class 1 Ford Transit Connect cargo van to a Class 7 Ford F-750 tractor rig. Every truck and van in the Ford Commercial Truck lineup will be all-new or significantly refreshed in the next 18 months.

Offered in Regular Cab, SuperCab and Crew Cab styles and in straight frame, dock height and an all-new dedicated tractor model for heavy towing applications, the 2016 F-650/F-750 features a bold look inside and out.

The new medium-duty truck lineup will be available in spring 2015.

5/21/14

The Wait Is Almost Over! Dealer Order Banks Now Open for All-New 2015 Ford Mustang

- Ford dealers can now begin placing orders for 2015 Mustang fastback

- 2015 Mustang fastback includes many new standard features such as fully independent suspension, push-button start, next-generation SYNC® AppLink™ and a choice of three powerful engines

- All-new Mustang EcoBoost® and Mustang GT available with 50 Years Appearance Package

For Ford Mustang fans everywhere, today they are one big step closer to experiencing the next generation as Ford has begun accepting dealer orders for the 2015 fastback.

Ever since the world got its first look at the all-new 2015 Mustang nearly six months ago, the anticipation has been palpable. Ford engineers have been racking up millions of testing miles, refining each system to make sure everything is just right before the first Mustangs reach customers later this year.

“From the six cities around the globe where we revealed the all-new Mustang, to auto shows to the recent 50-year celebration events, we’ve received an amazing response from people when they finally see the new model,” said Steve Ling, Ford car marketing manager. “This car is all-new with enhanced sophistication and craftsmanship, but it still exudes the essence of Mustang that’s been honed throughout its history.”

Customers can choose from three available powerplants for the 2015 Mustang, each of which can be paired with an upgraded six-speed manual or six-speed automatic transmission with paddle shifters:

- All-new 2.3-liter EcoBoost®, producing more than 305 horsepower and 300 lb.-ft. of torque and with projected class-leading fuel efficiency

- Upgraded 5.0-liter V8, generating more than 420 horsepower and 390 lb.-ft. of torque

- Upgraded 3.7-liter V6, producing more than 300 horsepower and 270 lb.-ft. of torque

In addition to a sleek new design and dramatically improved cabin, each 2015 Mustang adds an array of new standard features:

- Fully independent front and rear suspension for improved driving dynamics and ride quality

- Eight airbags including front, knee and side-impact protection for driver and front passenger

- Individual tire pressure monitor readouts for each wheel

- Rear view camera system

- High-intensity discharge headlamps with signature lighting

- Illuminated, locking glove box

- Leather-wrapped steering wheel with manual tilt and telescope adjustment

- Intelligent access, enabling the driver to enter without touching the key fob

- Push-button start

- SYNC® connectivity system with next-generation AppLink™ to control smartphone apps with simple voice commands; 4.2-inch color display and two USB ports

The ample standard equipment list can be further augmented with the availability of advanced technology features such as:

- Eight-inch, high-resolution touch-screen display and navigation

- Blind Spot Information System with cross-traffic alert upgraded with Doppler-effect radar sensors to provide both improved sensitivity at longer distances and better resistance to false alerts

- Adaptive cruise control and collision warning for the first time

- Track Apps provide a variety of on-track performance measurements for drivers

- Selectable drive modes feature lets the driver quickly adjust steering, throttle response, shift control and stability control settings by toggling between normal, snow-wet, sport and track modes

- Mustang GT easy to use electronic line lock and a launch control system that manages engine speed and brakes, giving drivers maximum and consistent acceleration at the track

A 50 Years appearance package is available for Mustang EcoBoost Premium and Mustang GT Premium models. The appearance package includes a chrome-accented grille, round 50 Years rear badge, 19x8.5-inch alloy wheels with 255/40R19 all-season tires, anniversary floor mats and unique seat and door-trim stitching.

The 2015 Ford Mustang fastback with 3.7-liter V6 starts at just $24,425 including destination and delivery charges in the United States. Mustang will be available from Ford dealers in North America this fall.

5/20/14

The World's Smallest Car Meets Ford's Biggest Van

The all-new 2015 Ford Transit features more cargo space than competing vans from Chevrolet and Ram, with up to 15.1 cubic-meters of space in Europe and 487 cubic-feet of space in the U.S. How big is that? Find out when the world's smallest production car, the Peel P50, meets Ford's biggest van!

5/19/14

Ford Dearborn Truck Plant Celebrates 10 Years of Built Ford Tough Trucks

Ford Motor Company is celebrating the 10-year anniversary of its groundbreaking Dearborn Truck Plant. As the centerpiece of Ford Rouge Center, Dearborn Truck Plant was conceived as Ford's vision of sustainable manufacturing and has served as flagship for the company's next generation of lean and flexible plants.

Dearborn Truck Plant has produced more than 2.6 million F-150 trucks since it opened in May 2004, and later this year, it will begin production of the all-new 2015 Ford F-150.

5/18/14

Ford Brings Custom Transit Connect Wagons to Maker Faire 2014; Makers Get a Chance to Meet the Unminivan

- Two new custom Ford Transit Connect Wagons, Hackmobile and Happy Mutant Mobile, will be on display at Maker Faire – an all-ages event for the do-it-yourself enthusiast

- Ford and MAKE magazine teamed up in the construction of Hackmobile, the ultimate Transit Connect Wagon for the do-it-yourselfer, and Happy Mutant Mobile, which was personalized for the Web-based magazine Boing Boing

- All-new Ford Transit Connect Wagon, the #unminivan, is available as a five- or seven-seat vehicle that can be paired with one of two fuel-efficient engines – a 1.6-liter EcoBoost® or a 2.5-liter four-cylinder

Ford and MAKE magazine will show two creative takes on personalizing the all-new Transit Connect Wagon as part of Maker Faire, an all-ages event celebrating the do-it-yourself spirit.

MAKE magazine put on the first Maker Faire in 2006 in the San Francisco Bay Area, bringing together tech enthusiasts, crafters, educators, hobbyists, engineers and artists. It has since grown, with several Maker Faire events taking place around the world. Last year, about 195,000 people attended the two flagship Maker Faire events, held in San Francisco and New York. This year, Maker Faire events will take place in more than 60 cities in North America and beyond.

Hackmobile and Happy Mutant Mobile Transit Connect Wagons will make a public appearance on Thursday, May 15, at TechShop in San Francisco before going on display at Maker Faire, Saturday and Sunday, May 17 and May 18, at San Mateo Event Center in San Mateo, Calif. The vehicles will also be on display at Maker Faire in New York later this year.

“Transit Connect Wagon is exactly what customers want it to be,” said Minyang Jiang, brand manager for Ford Transit Connect Wagon. “Whether it’s used as a people mover or to carry cargo, the spirit of the vehicle is in how it can be transformed by its owners to express their passions. We think these two vehicles are a perfect example of the unminivan, of how to inspire the imagination in a new way.”

Hackmobile, a fabricating workshop on four wheels, was the winner of MAKE magazine’s Ultimate Maker Vehicle Challenge, a competition that saw 10 teams vie to create the ultimate Ford Transit Connect Wagon for the do-it-yourself enthusiast. As part of winning the contest, Ford commissioned California-based builder CGS Motorsports to build Hackmobile.

The winning design team, Twin Cities Maker, is part of a Minnesota-based community nonprofit that operates a shop called Hack Factory, where members build projects and hold classes for the community.

The concept was for a Transit Connect Wagon to be designed and built around a machine the team dubbed “The Fabber” due to its use as a multipurpose tool in fabricating. Hackmobile has shelving and storage for tools to do woodworking, metalworking and 3D fabrication.

Happy Mutant Mobile was developed in collaboration with MAKE magazine and Boing Boing, a Web-based magazine devoted to technology and culture.

Boing Boing’s editors designed Happy Mutant Mobile to be as original as its name, serving as an official vehicle for the site.

The custom-designed exterior features a large screen that can roll down to show outdoor movies, a hood ornament that blows bubbles and LED signs mounted to the roof.

The interior is decorated in dark custom woodwork and green leather upholstery. It houses a mix of oddities and knickknacks, a 3D printer, camera equipment, magazine rack and computer equipment.

Theresa Contreras of California-based LGE*CTS Motorsports, which served as builder on the project, said the whimsical design features, like the bubble machine on the hood, make it one of the most unique builds the team has worked on.

“Transit Connect is a great platform for any build of this magnitude, or for the weekend warrior, for that matter,” Contreras said. “It’s amazing that the minute everyone lays eyes on this vehicle, they start thinking about how they would use it. I’ve heard everything from office desks to mountain bikes to band equipment. The unminivan can be a vehicle for everyone.”

The 2014 Transit Connect Wagon went on sale in North America earlier this year as an affordable alternative to customers looking for something new and functional in a five- or seven-seat people mover. With its dual sliding side doors, fold-flat second- and third-row seating, a maximum payload of 1,270 pounds, more than 100 cubic feet of cargo space, choice of a rear liftgate or side-hinged cargo doors and a starting MSRP of around $25,000, Ford Transit Connect Wagon takes adaptability to a new level.

5/17/14

Copy of Extreme Longboarding | Ford One Tank Adventure Videos

Watch as filmmaker Devin Super Tramp goes on a one-tank adventure with the Ford Focus ST. This amazing longboarding adventure was brought to you by a company that's all about MPG AND. Let Ford take you on your one-tank adventures because, at Ford, And is better.

5/16/14

New Ford Technical Support Center to Increase Vehicle Performance On- and Off-Track

- Ford reinforces commitment to racing and performance car development with announcement of new Ford Technical Support Center in Concord, N.C.

- Expected to be fully operational later this summer, the facility will serve as a center for Ford Racing technical support and for racing teams to develop and test their cars; center will eventually support development of future Ford performance vehicles

- Technical center’s full-motion platform simulator will allow race teams to optimize their setups for individual track configurations, and for drivers to buckle in and practice driving a track ahead of an upcoming race weekend

Ford announced the opening of its new Ford Technical Support Center in Concord, N.C. today. The state-of-the-art facility will add an array of tools to develop future performance vehicles and help increase Ford’s overall success in motorsports.

Expected to be fully operational later this summer, the 33,000-square-foot building will serve as a center for Ford Racing technical support and for teams to develop and test their cars for competition. The location was selected because of its proximity to the NASCAR research and development center and a majority of race car team headquarters.

“Motorsports and product development at Ford are interlinked, and this new center will house advanced tools that will serve both our race teams and the development of future Ford performance vehicles,” said Raj Nair, group vice president, Ford global product development.

Beyond its direct and immediate effect on Ford Racing, the new technical center with its advanced simulation and measurement tools is just the latest investment by Ford in its pursuit to offer a profitable lineup of performance vehicles. The new infrastructure will allow swifter and smarter leverage of the latest in product development technology.

Ford offers one of the most complete and accessible lineups of performance vehicles of any full-line manufacturer. From the growing popularity of its Sport-branded models including the EcoBoost® V6-powered Explorer Sport, to the award-winning Fiesta ST and its Focus ST stablemate, Taurus SHO, to the SVT Mustang GT500 and F-150 SVT Raptor, to extreme performance RS derivatives, Ford provides true performance options throughout its model range.

“Performance is a critical and growing business for Ford,” said Jim Farley, Ford executive vice president, global marketing, sales and service and Lincoln. “We recognize our customers want vehicles that offer great fuel economy, leading technology and a great driving experience. Our new technical center is another tool that will help us continue to grow our performance vehicle business around the world.”

Initially, the facility will focus on supporting NASCAR teams in all three major touring divisions, but will eventually expand to include other Ford Racing teams participating in other series.

“This facility is an investment in advanced Ford Racing technical tools that will support our goal of winning races and championships,” said Jamie Allison, director, Ford Racing. “It also provides us with expansion capabilities as we support our broader array of Ford teams from NASCAR, the TUDOR United SportsCar Championship, IMSA, Rally and Global RallyCross, NHRA and other series.”

The centerpiece of the building is a full-motion platform simulator that will allow Ford Racing teams to optimize their setups for individual track configurations, and for drivers to practice driving a track ahead of an upcoming race weekend. Similar technology has been used in Formula One. After the simulator has been proven through racing, Ford will apply that knowledge to further improve vehicle dynamics on its high-performance street vehicles.

“We have enhanced our vehicle dynamics simulation tools to lead the development of Ford Racing cars in NASCAR and IMSA, as well as our street products,” said Nair. “The driving simulator will help us to push handling optimization to the next level so that our cars can be fast right off the trailer, allowing our teams to focus on fine-tuning changes when they get to the track.

“The simulator can also be used to make continual adjustments to advance the car setup for the race weekend based on what the teams see in early practice sessions,” added Nair.

In addition, the simulator will help hone communication between driver, crew chief and engineer, while also refining predictability and accuracy of simulation software.

The support facility will also serve as a parts distribution warehouse. The various pieces of test equipment include:

- Kinematics machine: This machine can test and measure suspension kinematics – camber, toe, scrub and various loads with tires and springs. Race teams use this weekly to set up their front suspensions for different track configurations

- Chassis torsional twist rig: Used to quantify the chassis structurally in the torsional mode – the key parameter for a chassis. It can be used to determine the entire torsional stiffness of the car, the stiffness of the chassis independently, or the influence of various components on the car

- Vehicle center of gravity machine: This is used to precisely measure the center of gravity height of a completed car. It can be used to quantify improvements over time. Race teams generally use the machine once a quarter to gauge progress and test their latest theories

- Coordinate measurement machine: This machine enables teams to measure their components for quality control and to build simulation models, which allows them to make sure their cars comply with regulations

5/15/14

Ford Transit Paint Process-Kansas City Assembly Plant

The two-wet monocoat paint process reduces the paint application process from three layers to two and drying cycles from two to one, including a single co-bake processing of the monocoat and primer surfacer. The process uses a new paint formula that combines color with the properties of a clear coat. Removing the need for a separate clear coat application increases overall paint efficiency and reduces energy use and the physical space needed for paint operations.

5/14/14

Go Further - Ford Escape Commercial

You never know what's going to come your way in this life. But if it takes both hands to carry, the Ford Escape and its available foot-activated liftgate will help make it easier to take it with you.

5/13/14

Ford Mustang Gets Fine Art Treatment: U.K. Sculptor Robin Bark Creates 50 Years Limited Edition Pieces

- U.K.-based Robin Bark has created a limited-edition 1965 Ford Mustang fastback sculpture to celebrate 50 years of the iconic sports car

- Bark captures the essence of the original Mustang in a handcrafted piece that evokes power and motion

- Only 500 individual works will be produced, each cast in solid aluminum, polished, numbered and signed by the artist

Bark is well versed in the arts, with experience in industrial design, graphic design ceramics and metalwork. He frequently blends his passion for automobiles with his love of art.

“I think I was drawing cars the moment I was born,” said Bark. “Growing up in South Africa, I wanted to design cars, but there wasn’t much call for it, so I switched from industrial design to graphics, which took me into advertising for a time.”

Bark eventually returned to the U.K. and became an art teacher, where he experimented in new mediums including metal casting. He went on to develop a series of cast-aluminum sculptures of classic motorbikes and sports cars.

Bark starts a project with an extensive series of photos of the car, which he then translates into rough engineering drawings. As his first American car sculpture, Mustang came as a unique challenge for Bark.

“Mustang is a very different shape from the earlier cars I had done, which were more classically streamlined,” he said. “I look for what the designers were trying to achieve with shapes, and try to capture the essence of the car while also imparting a sense of motion to a static object.”

Bark shapes an initial model in clay. The fundamental shape is then transferred into a resin version, which polishes to work out how the light reflects off the contours. The resin model then becomes the pattern to cast an aluminum prototype. Bark stays true to Mustang’s iconic design while using as little detail as possible, avoiding lines and features that distract from the fundamental shape of the car.

“I tried to reveal its story as it reflects in the light,” he explained.

“From the shark-bite nose to the long, sweeping line of the fastback roof to the tri-bar taillamps, Mustang has a quintessential profile that makes it easily recognizable to everyone on the road,” said Moray Callum, Ford vice president, global design. “Robin Bark has captured the essential nature of one of the greatest Mustangs in his sculpture, creating an object of art that appears to be fluid motion.”

Shaped to the sculptor’s satisfaction, the resin model is sent to a specialist casting pattern maker. Working with a traditional foundry based in Guildford, U.K., the raw aluminum castings are produced in batches of 10 at a time. The foundry specializes in small batch production of unique castings and regularly creates reproduction parts for vintage race cars such as cylinder heads and gearbox casings for vintage 1930s-era grand prix race cars.

Each casting is polished to a finished piece that is signed and numbered by the artist and placed in a commemorative wood box. No more than 500 of the 1965 Mustang fastback sculptures will be produced.

Bark has shown his prototype at Mustang Club events in France and the U.K., where fans responded with great enthusiasm to his interpretation of the original Ford Mustang, ordering several pieces.

The limited-edition sculptures are available through the artist’s website, robinbark-motorart.com.

5/12/14

Go Further - Ford Fusion Commercial

Life comes at you from every direction. When you're on the road, the Ford Fusion with its available BLIS® with Cross-Traffic Alert and available rear-view camera will help you keep tabs on it.

5/11/14

Ford Fusion Energi Adventure: Charging Station

The winner of the Ford Fusion Energi Adventure received a road trip of their choosing and a 2013 Ford Fusion Energi!

In this video, the winner, Justine, learns about locating charging stations for her Ford Fusion Energi using MyFord Mobile.

5/10/14

Ford Fusion Energi Adventure: Quiet Drive

In this video, Justine, is amazed at how quiet the vehicle is while driving.

5/09/14

20 Years Strong – Ford Warriors in Pink Drives the Conversation with New Survey on Breast Cancer Awareness

- National survey shows that despite awareness of breast cancer as a leading health concern, women are not talking enough about breast health

- Ford Warriors in Pink issues strong call to action to drive more conversations about breast health

- Now in its 20th year, Ford continues in the fight against breast cancer, dedicating more than $125 million for the cause to date

Ford Motor Company and its Warriors in Pink campaign kicks off its 20th year of support in the fight against breast cancer by issuing a strong call to action encouraging women to drive more conversations on breast health. Over the past 20 years, Warriors in Pink has observed how informed conversations can drive awareness and inspire women to be proactive about their breast health.

A relentless change agent in the fight against breast cancer, Warriors in Pink has embraced its role as a catalyst to inspire honest conversations among women. A recent national survey conducted by Ford Warriors in Pink shows that despite being a leading health concern for women, important breast health conversations are not happening enough – particularly between mothers and daughters.

“Through Warriors in Pink, Ford continues to be a unifying force in driving awareness for breast cancer,” said Joe Hinrichs, president of The Americas, Ford Motor Company. “This year is especially meaningful to us as we mark our 20th anniversary and honor the strength and courage of all the survivors who have shared their stories with us throughout their journey.”

Driving the conversation

To examine the state of conversation around breast health, Ford Warriors in Pink commissioned the Drive the Conversation survey among U.S. adult women, with specific emphasis on mothers and daughters.

The survey reveals a disconnect between what women care about and what they actually talk about. Both mothers and daughters admit they are more likely to talk about breast health if the other initiates the conversation, and 45 percent of daughters wish they were comfortable enough to talk to their mother about breast health.

While mothers and daughters are committed to and comfortable with having important conversations, they are not having enough conversations about breast cancer. Only 41 percent of mothers report discussing breast cancer with their daughters, and 52 percent of daughters admit that it does not occur to them to talk to their mother about breast health.

One in eight women is diagnosed with breast cancer every year, yet about one third of women still don’t think about breast health until it is mentioned by their doctor.

“As a mother myself and the youngest of three siblings, I felt that this was a great opportunity to put more light on the important health conversations we should be having more of with our loved ones,” said Tracy Magee, Ford brand experiential marketing manager. “And creating a comfortable space to have these conversations is critical.”

According to the survey, the majority of women (68 percent) believe that a vehicle provides a private and safe setting for important health conversations, with 38 percent admitting they sometimes wait to have important conversations until they are in the car.

The power of 20

In honor of its 20 years in the fight, Ford continues its commitment to the Models of Courage program highlighting 20 individuals, each sharing their inspiring experiences with breast cancer.

“We are deeply honored to welcome these 20 courageous and inspiring women and men to the Models of Courage program and are proud to have them represent Warriors in Pink – each with their own heartfelt story to share. They are true embodiments of our warrior spirit,” says Magee.

The Models of Courage will share their stories, inspiring hope and helping others face their battles throughout the year at national and community events, and in Warriors in Pink communications.

Wear the warrior spirit

This month, Ford is also introducing the 2014 Warriors in Pink line of apparel and accessories dedicated to the fight against breast cancer. The Warriors in Pink apparel collection features bold symbols that signify hope and strength, and that embody the warrior spirit of taking charge, harnessing power and standing together. This year, the collection will feature new items including a hoodie T-shirt, a lightweight jacket and a men’s polo and necktie, as well as best-selling accessories such as the annual women’s scarf and an updated versatile tote.

One hundred percent of the net proceeds from all warrior wear and gear sales is dedicated to the fight against breast cancer benefiting Warriors in Pink’s four charity partners: The Pink Fund, Susan G. Komen, Dr. Susan Love Research Foundation and Young Survival Coalition.

The 2014 Warriors in Pink collection will be available at www.fordcares.com.

5/08/14

Oklahoma, Dallas Order 300-Plus CNG-Capable Ford F-150 Pickups As Demand Grows for Alternative Fuel Option

- The state of Oklahoma and its agencies to buy 256 Ford F-150 trucks prepped to run on compressed natural gas; Dallas orders 65 for its fleet

- 2014 F-150 available with gaseous-fuel prep option on 3.7-liter V6 engine; can run on CNG or liquefied petroleum gas (also called propane autogas)

- By summer, Ford will offer eight vehicles that can run on clean-burning, affordable CNG; the company is on track to sell more than 15,000 such vehicles in 2014

The state of Oklahoma, its agencies and the city of Dallas have ordered a total of 321 Ford F-150 pickups that can run on compressed natural gas.

Since 2010, Ford CNG-prepped truck sales have increased more than 250 percent, said Jon Coleman, Ford fleet sales manager. Cumulative sales are expected to exceed 50,000 trucks by the end of the year, and Ford expects demand for CNG-prepped vehicles to continue growing as more fleet customers recognize the economic and environmental benefits of this clean-burning fuel.

CNG-powered trucks lower costs and offer emissions benefits, and the alternative fuel is domestically produced, Coleman explained. Operating costs can be as low as one third that of conventional vehicles. Typically, the fuel savings cover the cost of conversion within three years.

“For fleet customers in Oklahoma, Texas and other states, a CNG F-150 really makes sense,” Coleman said. “The fuel is more affordable and widely available, and it reduces greenhouse gases and pollutants that cause smog.”

The 2014 F-150 is available with a gaseous-fuel prep option for the 3.7-liter V6 that can run on CNG or liquefied petroleum gas. CNG/LPG engine prep from the factory costs $315. The customer then chooses a Ford Qualified Vehicle Modifier to supply fuel tanks, fuel lines and unique fuel injectors. Upfits run approximately $6,000 to $9,500, depending on tank capacity.

For fleet managers, CNG conversions can provide stability against fluctuating fuel prices, lower vehicle operating costs and reduce pollutants. CNG sells for a national average $2.11 per gallon of gasoline equivalent, and is as low as $1 in parts of the country. By comparison, the national average for unleaded regular gas is $3.67 per gallon.

Customers can also accelerate the payback period by taking advantage of a growing number of incentives issued by states such as Oklahoma.

CNG expansion

Oklahoma Gov. Mary Fallin is leading a coalition of 22 states seeking to use more CNG vehicles in their fleets. CNG is abundant in this country and reduces America’s dependence on foreign oil. CNG also lessens the environmental impact of greenhouse gas by 20 percent and reduces smog-producing pollutants up to 90 percent.

Fallin announced the CNG project at her inaugural Governor’s Energy Conference in 2011. Since then, she has worked with other Oklahoma officials and governors from other states, met with Ford and other automobile manufacturers, and received bids to add more CNG vehicles to the state’s fleets.

“I am excited about Oklahoma’s partnership with Ford Motor Company as we work to support energy efficiency, cost savings and the use of clean-burning American-made energy,” Fallin said. “Ultimately, converting our state fleets to CNG will save millions in taxpayer dollars.”

CNG prices in Oklahoma vary from $1.07 to $2.49 per gallon of gasoline equivalent. The average statewide price for a gallon of regular gas is $3.43. Fuel bills could be reduced as much as 67 percent with CNG vehicles, Coleman said.

Arkansas, Colorado, Louisiana, Mississippi and Texas have expressed interest in Ford CNG-capable vehicles, Coleman said.

The specially equipped bi-fuel F-150 model purchased by Oklahoma features two storage tanks – the regular factory gasoline reservoir and a supplementary CNG tank. Combined, this gives the light-duty truck a range of up to 750 miles, depending on the size of the tanks. The most common configuration allows fleet operators to go 450 miles on CNG alone and another 300 miles on regular gas.

Most CNG options

By this summer, Ford will offer eight commercial vehicles with a gaseous-prep option, more than any other full-line manufacturer:

- 2015 Transit Connect van and wagon

- 2015 Transit van, wagon, cutaway and chassis cab

- 2014 E-Series van, wagon, cutaway and stripped chassis

- 2015 F-Series Super Duty pickup

- 2015 F-Series Super Duty chassis cab

- 2015 F-650 medium-duty truck

- 2015 F53 and F59 stripped chassis

- 2014 F-150 light-duty pickup

Power of Choice

CNG/LPG prepped vehicles are part of Ford’s commitment to offering a wide range of alternative fuel options to customers to help meet their mileage and driving needs, including EcoBoost, hybrid, plug-in hybrid, battery electric, Flex Fuel and B20 biodiesel.

5/07/14

One-of-a-Kind 2015 Ford Mustang 50 Years Convertible Being Raffled to Support Multiple Sclerosis

- A single 2015 Ford Mustang 50 Years convertible will be produced for raffle, with proceeds supporting multiple sclerosis research

- The Mustang GT being raffled is the only 2015 convertible to be built with a performance pack and select content from the 50 Year Limited Edition fastback

- The winning ticket will be selected in Mustang Alley on Aug. 16, 2014 during the annual Woodward Dream Cruise

Ford continues its longstanding support of the National Multiple Sclerosis Society by offering a one-of-a-kind 2015 Mustang 50 Years convertible to be raffled off this summer. The winner of this exclusive convertible featuring select content from the 50 Year Limited Edition fastback will be announced in Mustang Alley in Ferndale, Mich., on Aug. 16, 2014 during the annual Woodward Dream Cruise.

“We’re thrilled to be able to work with and help The National MS Society again,” said Raj Nair, Ford group vice president, global product development. “As pleased as we are to be able to help financially with the Society’s No Opportunity Wasted research project, we also feel it’s important to help raise greater awareness of this terrific program. That we’re creating one – and only one – Mustang GT 50 Years convertible for the Society shows how much we respect and support their efforts.”

The car will be among the first regular production 2015 Mustang GT convertibles built this fall. Power comes from a 5.0-liter V8 generating more than 420 horsepower and more than 390 lb.-ft. of torque, paired with a six-speed manual transmission. This will be the only 2015 Mustang convertible built with a special performance pack that includes 19-inch Pirelli P-Zero summer tires, Brembo six-piston painted front brake calipers and a limited-slip differential.

Like the recently announced 50 Year Limited Edition fastback, the convertible features a number of unique elements that distinguish it from other 2015 Mustangs:

- Wimbledon White exterior paint

- Chrome-accented grille with corralled pony emblem

- Chrome accents around the tri-bar taillamp lenses

- Axle spin-finish aluminum instrument panel trim

- Rear decklid badge with “GT 50 Years” identification

- Two-tone cashmere and black leather seats

- Contrasting cashmere stitching on instrument panel, steering wheel, shift boot, door inserts and seats

- Loop-carpet floor mats with cashmere stitching and suede binding

- 19-inch Y-spoke wheels inspired by the chrome steel wheels offered on original Mustang

- Owner’s guide in a leather portfolio with “50 Years” badge on the outside

This special Mustang also includes a badge on the instrument panel, engraved with the signature of Ford Motor Company Executive Chairman Bill Ford, and serial number 0001 of 0001.

A limited number of raffle tickets are on sale now and can be purchased through National MS Society, Michigan Chapter and Ford Motor Company, while supplies last. Tickets are $20 each. Ticket requests can be placed online anytime at www.ford4ms.com. Raffle tickets can also be reserved by phone at 800.243.5767 between 8 a.m. and 8 p.m. EDT Monday through Friday.

The winner does not need to be present when the lucky ticket is drawn at the Woodward Dream Cruise. The winner is responsible for title, taxes and registration.

5/06/14

Coco Jones Learns to Drive a Ford Fiesta

We gave Coco Jones a Ford Fiesta for her Sixteenth birthday! Watch from inside the Fiesta as she has fun behind the wheel for the first time.

5/05/14

Ford Sells 500,000th EcoBoost Engine for F-150 As Customer Preference Shifts to V6 Engines

- More than 56 million gallons of gasoline have been saved as Ford truck customers are choosing V6 EcoBoost® engines – more than all the fuel savings of electric and plug-in electric vehicles ever sold

- Since 2010, Ford accounts for 91 percent of industry growth in V6 truck sales; all-new 2015 Ford F-150 will feature predominant V6 engine lineup

- Ford 3.5-liter EcoBoost engine represents 45 percent of F-150 pickup truck sales in 2014, the best-selling engine in the lineup

Ford, America’s truck leader for 37 years, marks a major milestone with the sale of its 500,000th 3.5-liter V6 EcoBoost®-equipped F-150.

Just more than three years after its introduction, popularity of Ford’s 3.5-liter EcoBoost engine continues to grow among F-150 customers as its cumulative fuel savings continue to increase.

In the past 38 months, F-150 EcoBoost owners collectively have saved an estimated 56.8 million gallons of gas on an annual basis. According to the U.S. Environmental Protection Agency, that’s equal to:

- The annual greenhouse gas impact of 413,895 acres of U.S. forests

- A city in which 70,000 homes going without electricity for a year

- 6,685 tanker trucks’ worth of gasoline

- Installing 139 wind turbines

For the fourth month in a row, more than 57 percent of retail sales of Ford F-150 light-duty trucks are powered by V6 engines – reversing 47 years of V8 engine dominance in the industry. More than 45 percent of these sales are trucks equipped with Ford’s 3.5-liter EcoBoost.

Over the last three years, retail registrations of light-duty pickups powered by V6 engines grew more than 600 percent, with F-150 directly responsible for 91 percent of that growth, based on Ford analysis of Polk retail registration data.

“We expect those numbers to hold for the rest of the year,” said Doug Scott, Ford truck group marketing manager. “It really is amazing when you consider we are doing that with just two V6 engine choices – the 3.5-liter EcoBoost and the 3.5-liter Ti-VCT engine. When we come out with the new 2015 F-150, we will offer three different V6 engines, so there is potential for further growth.”

The segment-exclusive technologies built into every EcoBoost engine, including turbocharging and direct fuel injection, are particularly relevant for truck customers. This combination of turbocharging and direct fuel injection delivers a wealth of low-end torque and maintains it across a broad rpm range, which is key in towing applications.

The 3.5-liter EcoBoost truck engine delivers 420 lb.-ft. of torque and 365 horsepower to enable towing of up to 11,300 pounds – more than enough to tow a fully loaded, three-horse trailer or a large boat. Plus, this engine does it all on regular fuel and with outstanding fuel economy.

“Truck customers should think of the EcoBoost truck engine as a gas-powered engine with diesel-type capability and characteristics,” said Jim Mazuchowski, Ford V6 engines program manager. “The twin turbochargers and direct injection give it the broad, flat torque curve that makes towing with a diesel so effortless and hard acceleration so much fun.”

In the last three years, no competitor has eclipsed a 20 percent take rate for V6 engines in half-ton trucks. It’s been a predominantly V8 crowd, until the introduction of the Ford EcoBoost V6.

“Today’s customer doesn’t hold to the old notion that a truck must be powered by a V8 engine,” Scott said. “Just five years ago, you would have had a hard time making a case for V6 truck engines. Not today. Now, it’s all about fuel effectiveness. Customers are looking for the best combination of city and highway mileage, horsepower, torque, towing capacity, payload and value, asking the key question, ‘What is the most productive, efficient package for the work I need to do?’.”

That efficiency a V6 engine delivers is starting to have a significant impact on the environment. By moving half a million F-150 customers out of V8s and into V6 engines, Ford has saved more than 56 million gallons of fuel – more than all of the fuel saved from every electric and plug-in electric car ever sold.*

That gap will only widen as time goes on, Scott said.

Along with the 3.5-liter Ti-VCT and 3.5-liter EcoBoost V6 engines, the all-new 2015 Ford F-150 will offer a new 2.7-liter EcoBoost engine with standard Auto Start-Stop, built in Lima, Ohio.

Production of EcoBoost is supported, in part, by Ford's green partnership with the U.S. Department of Energy. Ford has 11 facilities in the U.S., including retooling of Cleveland Engine Plant where EcoBoost is made, participating in the Advanced Technology Vehicles Manufacturing Loan Program. This green loan program helped to develop advanced technologies and strengthen American manufacturing across the country.

*Note: This assumes people move out of a conventional, midsized hybrid into a more efficient vehicle that never or rarely runs on gas for 15,000 miles a year.

5/04/14

Ford Transit Connect Wagon: The Unminivan Breaks from Traditional Seven-Passenger People Mover

- A different kind of seven-seat people mover, the all-new 2014 Ford Transit Connect Wagon combines style, efficiency and adaptability in an affordable package

- Transit Connect Wagon is the #unminivan, offering class-leading cargo and passenger space, and an EPA-estimated 29 mpg highway when equipped with 1.6-liter EcoBoost®

- With the convenience of dual sliding side doors, fold-flat second- and third-row seating, a maximum payload of 1,270 pounds, choice of a rear liftgate or side-hinged cargo doors, and starting around $25,000, Transit Connect Wagon takes adaptability to a new level

Think of the all-new 2014 Ford Transit Connect Wagon as the #unminivan.

Fuel efficient, flexible, uniquely styled and fun to drive, Transit Connect Wagon is an affordable people mover for families and active individuals who want to be ready for whatever life brings.

“Ford’s all-new Transit Connect Wagon is unlike anything else,” said Minyang Jiang, Transit Connect brand manager, Ford Motor Company. “It drives like a car, has the flexibility of a utility and can haul the payload of a full-size pickup. This new wagon is a great combination of affordability and functionality – a unique global vehicle we’re proud to offer our customers.”

Transit Connect Wagon is now on sale in North America at a starting price of around $25,000. It is available in two wheelbase lengths – a five-passenger with removable seating or a seven-passenger with fold-flat seating. It offers sliding side doors, a choice of a rear liftgate or side-hinged cargo doors, more than 100 cubic feet of cargo space and a maximum payload of 1,270 pounds. Available trim levels include XL, XLT and the range-topping Titanium.

Customers can select from two fuel-efficient four-cylinder engines – the standard 2.5-liter with an EPA-estimated rating of 28 mpg on the highway, and a 1.6-liter EcoBoost® with an EPA-estimated rating of 29 mpg highway.

Both engines are paired to a six-speed SelectShift® automatic transmission designed for smooth driving around town and efficiency on the highway.

Award-winning Transit Connect: Fun to drive, Built Ford Tough

Transit Connect Wagon shares Ford’s global C-platform with the sporty Focus model, making it easy to maneuver in parking lots while being fun to drive on curvy roads. Torque vectoring control technology, which uses the brakes to provide stability through turns, is responsible for the fun handling characteristics the vehicle offers.

Transit Connect Wagon has been designed, engineered and tested to meet Ford’s rigorous Built Ford Tough durability standards. The testing equivalent of more than 3 million miles includes 250,000-plus miles in such demanding conditions as gravel roads, tracks that mimic rugged environments and pothole-damaged pavement.

The vehicle was introduced in Europe in 2002, and now, the 2014 Transit Connect van has been named International Van of the Year by a panel of European auto media. It debuted in North America in 2009, quickly becoming a fleet favorite for its size and capability as a hauler of people and cargo.

Now, with the arrival of the all-new Transit Connect Wagon, retail buyers have a fresh alternative to the traditional people mover.

The Transit Connect lineup posted its strongest annual sales in 2013, with just under 40,000 units sold, up 12.7 percent from 2012. Since its U.S. introduction, more than 150,000 Transit Connect models have been sold. 2014 so far has been the best year for sales of the wagon model.

California is the largest retail area for Transit Connect Wagon and van. The growth in this market is 300-plus percent more than the minivan segment, which grew by about 10 percent in the first quarter of 2014.

As unique as its buyer

Transit Connect Wagon and Transit Connect van offer spacious interiors and customization options that allow owners to personalize the vehicle to their lifestyle. Ten custom-built Transit Connect vehicles were showcased at the 2013 Specialty Equipment Market Association show in November, demonstrating a range of potential uses – from a cross-country cruiser loaded with technology to a mobile video gaming station.